What does HPL and CPL mean?

What does HPL and CPL mean?

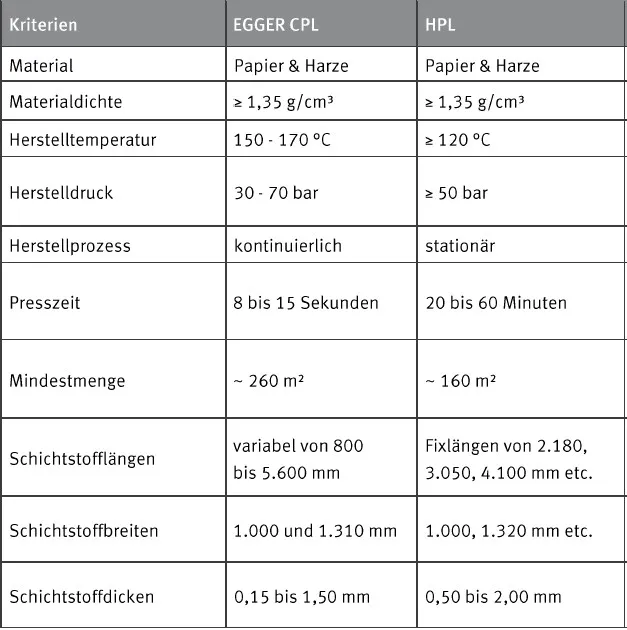

CPL stands for Continuous Pressed Laminates. HPL stands for High Pressure Laminates (HPL with a thickness of > 2 mm are according to standard EN 438 compact panels).

What is special about the HPL coating on our black matte furniture?

Our HPL laminate impresses with its high abrasion, impact, and scratch resistance. It is ideal for horizontal as well as heavily used surfaces. The super matte surface feels velvety warm and is characterized by its excellent anti-fingerprint properties. This makes our HPL laminate unique and universally applicable.

Are there any special care instructions for our HPL coating?

The HPL coating does not require special care due to its resistant and hygienic, dense surface. The surface is generally easy to clean. It is important to note that sanitary cleaners or cleaning agents with abrasive components should not be used for cleaning, as such cleaners can cause changes in gloss level and scratches.

What distinguishes HPL and CPL?

The term CPL already provides a hint about the manufacturing process, meaning CPL is produced in continuously operating double belt presses with a pressing pressure between 30 and 70 bar and temperatures between 150°C and 170°C. Depending on the laminate thickness and press zone length, the feed rate varies between 8 and 15 m/min.

HPL is produced in discontinuously operating multi-daylight presses with a pressing pressure between 50 and 90 bar and temperatures of > 120°C. Very often, the pressure in connection with the manufacturing process of laminates is also given in Mega-Pascals (MPa). The multi-daylight presses have between 10 and 20 levels, and each level accommodates approximately 8 laminate sheets with a nominal thickness of 0.50 to 0.80 mm. Depending on the press loading and the maximum temperature, the complete pressing cycle including cooling takes between 20 and 60 minutes.