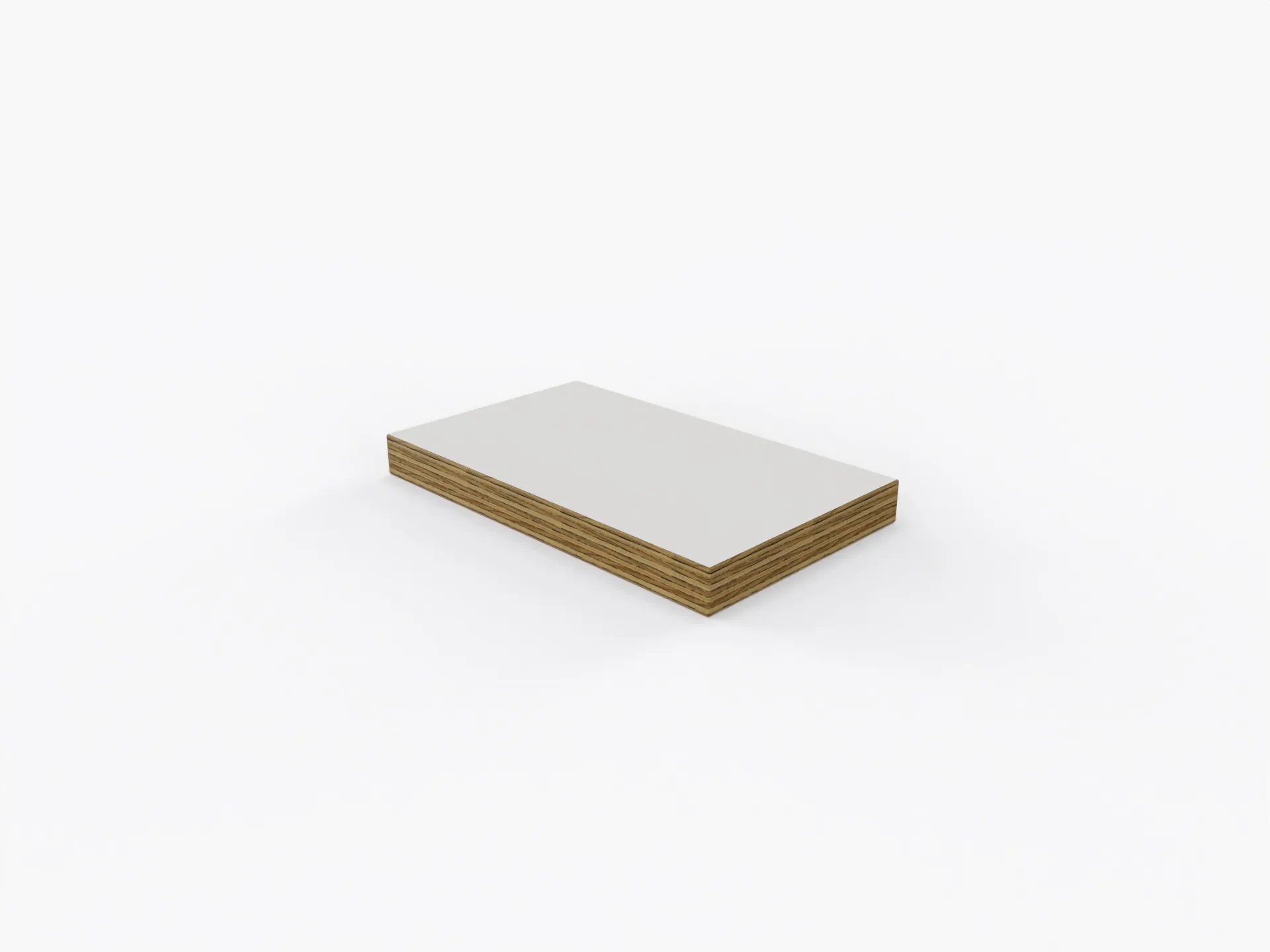

Was bedeutet HPL und CPL?

CPL ist die Abkürzung für Continuos Pressed Laminates

HPL ist die Abkürzung für High Pressure Laminates (HPL ab einer Dicke von > 2 mm sind gemäß Norm EN 438 Kompaktplatten)

Was ist das besondere an der HPL-Beschichtung unserer schwarz matten Möbel?

Unser HPL Schichtstoff überzeugt durch seine hohe Abrieb-, Stoß- und Kratzfestigkeit. Er eignet sich ideal für horizontale sowie stark beanspruchte Flächen. Die supermatte Oberfläche fühlt sich samtig warm an und zeichnet sich durch ihre sehr gute Anti-Fingerprint Eigenschaft aus. Das macht unseren HPL Schichtstoff einzigartig und universell einsetzbar.

Gibt es Besonderheiten bei der Pflege unserer HPL-Beschichtung?

Die HPL-Beschichtung bedarf wegen seiner widerstandsfähigen und hygienischen, dichten Oberfläche keiner besonderen Pflege. Die Oberfläche ist im Allgemeinen leicht zu reinigen. Zu beachten ist, dass zur Reinigung keine Sanitärreiniger oder Reinigungsmittel mit scheuernden Bestandteilen verwendet werden, da solche Reiniger zu Glanzgradänderungen und Kratzern führen.

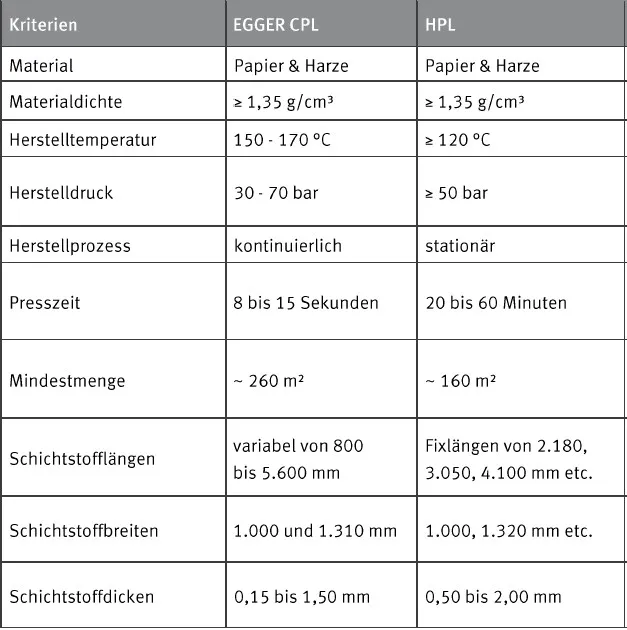

Was unterscheidet HPL und CPL?

Bereits der Begriff CPL gibt einen Hinweis auf das Herstellverfahren, das heißt CPL wird in kontinuierlich arbeitenden Doppelbandpressen mit einem Pressdruck zwischen 30 und 70 bar und Temperaturen zwischen 150 °C und 170 °C hergestellt. Abhängig von der Schichtstoffdicke und der Presszonenlänge variiert die Vorschubgeschwindigkeit zwischen 8 und 15 m/min

HPL wird in diskontinuierlich arbeitenden Mehretagenpressen mit Pressdruck zwischen 50 und 90 bar und Temperaturen von > 120 °C hergestellt. Sehr häufig wird in Verbindung mit dem Herstellverfahren von Schichtstoffen der Druck auch in Mega-Pascal (MPa) angegeben. Die Etagenpressen haben zwischen 10 und 20 Etagen und jede Etage nimmt ca. 8 Schichtstoffplatten mit einer Nenndicke von 0,50 bis 0,80 mm auf. Abhängig von der Pressenbeschickung und der maximalen Temperatur dauert der komplette Presszyklus inklusive Rückkühlung zwischen 20 und 60 Minuten